High precision Moulds and Mechanical Parts

LMB is basically a 360° built-to-print mechanical company offering a series of co-design, prototyping, one-shot production, short series activities and serial production.

We offer

- Different families of specific and highly precise mechanical Tools and Actuators for Customer’s manufacturing activities

- Finished parts for different industrial sectors: Aerospace, Automotive, Sealing, Racing, Nautical, Abrasive, Motorcycles and more;

- Our renowned Italian quality and flexibility, together with a continuous R&D, offer a top support to quickly improve and react to intensive changing manufacturing activities on all fields;

- The high-precision mechanical processes on various materials, such as Carbon Steels, Alloys, Inox, Aluminum rods and die castings together with several applications in the field of surface and heat treatments developed by LMB are suitable for all our customers.

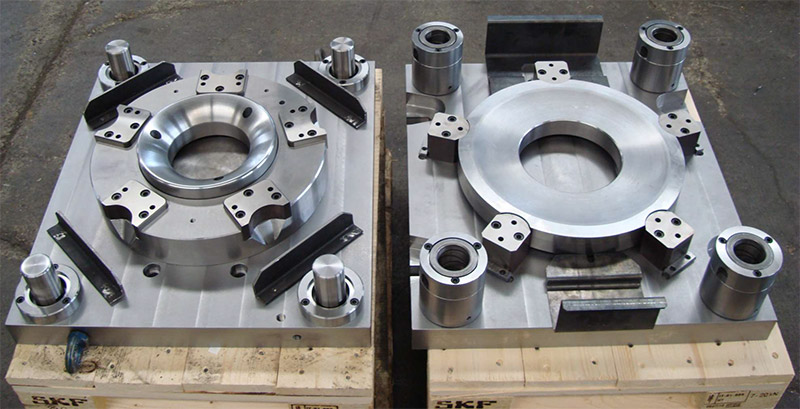

LARGE SIZE TOOLS

Manufacturing of large size mechanical tools for various industrial fields

Turning: maximum diameter 1.600mm (63”)

Milling : maximum cubic dimensions 1500mmx1000mm (59×40”)

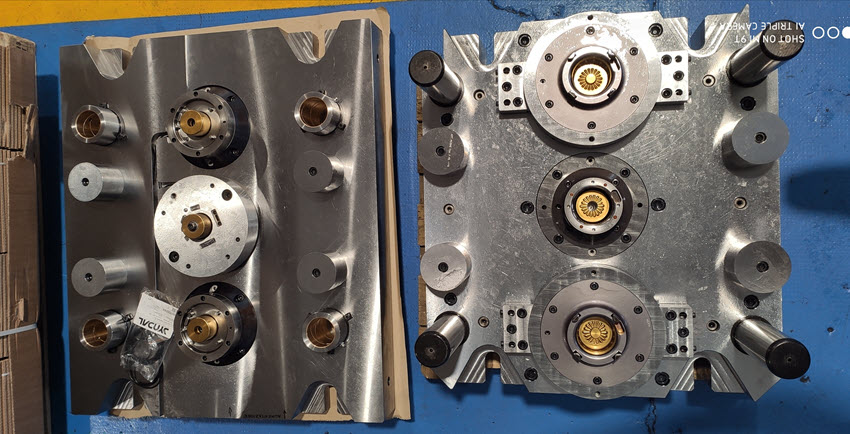

LMB SEALING TECHNOLOGY

Development and Manufacturing of moulds for rubber and polymer applications.

Global organization providing customers with high quality, custom-engineered products and special coatings and finishing.

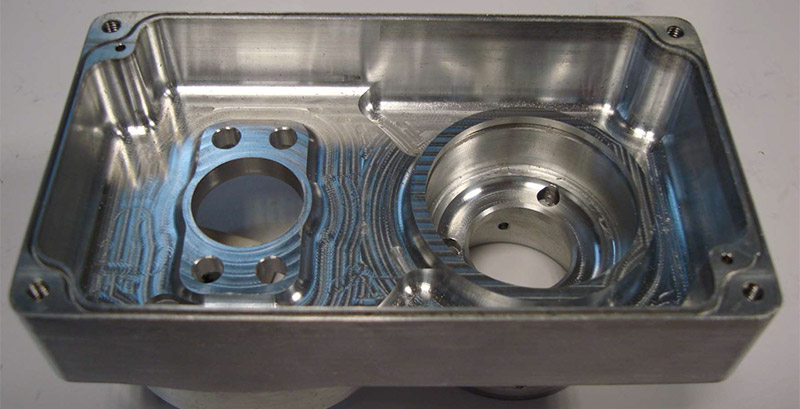

AERO TECH

LMB Aerospace offers high precision moulds and Precision mechanical machining for prototypes and special products.

ROLLERS

LMB is an historical and significant partner for the leading manufacturers of pipes and tubes (i.e. Marcegaglia, Arvedi, Padana Tubi, RivaGroup and others abroad)

LMB also manufactures a high range of rollers and moulds for automotive and agriculture wheels (Titan Group, Alcar Ruote and others).

ACTUATORS

Development and Manufacturing of actuators in cooperation with customers.

Project – Prototyping – Production

SPECIAL TOOLS

Tools for high precision and speed machines (Hatebur)

Special alloyed steels with nitriding or specific coatings for the Automotive industry

Typical materials used

- High alloyed Steel up to HRC (65-67)

- Aluminum (Ergal, 2xxx, 5xxx, 6xxx and 7xxx families)

- Heat treatments

- Special Surface Coatings: TiN, TiCN, TiZrN, TiA1N, ZrN, CrN, TiVCN, NICRAL, ALCRONA, Nitriding and others